Processing

ARPRO is a highly versatile material for molding a wide variety of finished parts. Our customers enjoy a wide product portfolio, significantly reduced process costs, improved performance and advanced environmental benefits. We are constantly developing new material grades and molding techniques, all in support of extending the range of ARPRO applications.

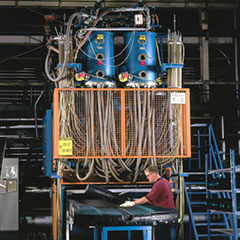

Molding

ARPRO can be molded into almost any shape.

It is air conveyed through pipes into a mold which is then heated using steam. This causes the material to fuse and take the shape of the mold.

The combination of key material properties and ingenious processing techniques, such as insert molding, enable component functionality to be enhanced.

We provide extensive technical support which includes onsite support. We also work closely with press and tool (mold) makers.

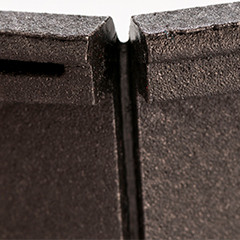

Fabrication

ARPRO can be used to fabricate custom packaging for heavy equipment, instruments, machinery and other industrial components, with parts being cut from molded blocks. This is most applicable for limited series demand where construction of a tool would not be economical, or where items to be protected are subject to frequent design change.

There are a number of cutting and adhesion techniques that can be used with ARPRO. Products are fabricated using skivers, saws, knives, water jets and suitable glue types.

Please visit ARPLANK.com to contact our plank distributor.

Aesthetics

The aesthetics of ARPRO are incredibly versatile, with options ranging from colors, surface textures, and fabric coverings. Snap fit designs, tight tolerances enabling precision parts, living hinges, custom surfaces and complex shapes make ARPRO a highly versatile and visibly pleasing material.