Packaging

Products such as medicines, prostheses and hygienic products place particularly high demands on packaging for sterility, protection, temperature-control and security, all of which are met by ARPRO.

Many of these demands are also present in other industries, for example automotive parts such as satnav systems need to be protected during transport both from accidental damage and static electricity. ARPRO is perfect for this.

Environment

In an industry with increasing concerns for environmental performance, reducing environmental impact through re-usable packaging is important. Use of re-usable packaging is extending beyond the automotive industry (where it is called dunnage) to traditional ‘delicate’ components such as glass, electronic or painted parts, as the next phase of minimising costs are found in process efficiencies.

Re-usable packaging containers not only protect parts in transit, but they make packaging and shipping easier (by reducing materials needed and time taken) and help to make unpacking and assembly more efficient.

Dunnage

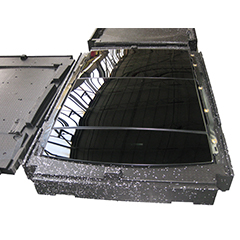

The durability of ARPRO allows for multi-use, transport ready packaging for many different types of components and sensitive products, from tiny needles for electronics components to large trays for automotive panorama roofs, with the ability for automated robotic installations.

General

Packaging for goods where more protection from multiple impacts is required, valuable goods that need special treatment and special care, or if there are long distance transports that need more advanced protection than usual, ARPRO is the material of choice.

Thermal containers

The lightweight, durable and thermal insulation properties of ARPRO make it a widely used ideal material for food packaging and catering boxes. ARPRO is also easy to clean, re-usable and designed for use in both hot and cold conditions.

ARPRO is available in many food approved grades.

ESDP

The ARPRO Electrostatic Discharge Protection (ESDP) grades assure greater protection from electrostatic discharge with a permanent surface resistance of less than 108Ω, promoting rapid static decay to protect against sparking.

ARPRO ESDP is used for moulding and fabricating packaging materials used for sensitive electronic equipment and other products where static discharge is undesirable.

Surfaces

The aesthetics of ARPRO are incredibly versatile, with options ranging from colours, surface textures, and fabric coverings.

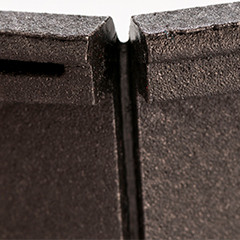

Tool surface treatment and finishing techniques make it possible to generate a wide variety of patterns in various sizes and depths. The excellent post expansion ability of ARPRO enables superb quality surfaces that can be used in visible aesthetic applications.

In addition, snap fit, tight tolerances enabling precision parts, living hinges and the ability for complex shapes make ARPRO a unique material.