Home > News > Innovation > From F1 to Space: Sabelt’s innovative Space Brick made from ARPRO EPP

Publication date: 01.08.2024

From F1 to Space: Sabelt’s innovative Space Brick made from ARPRO EPP

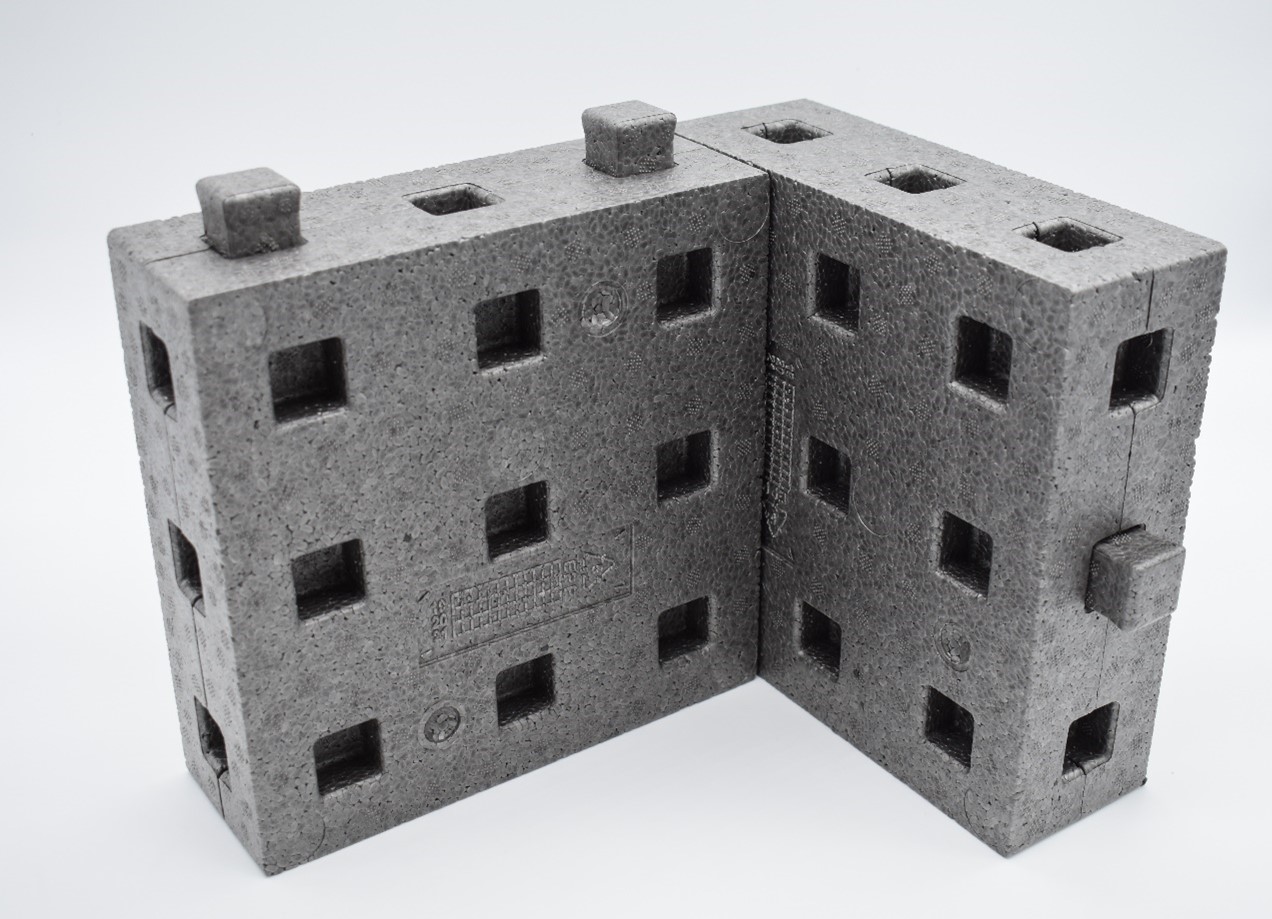

The Space Brick is a unique flame retardant modular element for deep space habitation hubs and moon base buildings. This lightweight mono-material solution is also compatible with space vehicles.

For the selection of the Space Brick material, the compulsory factor was the resistance to the space flammability test. Material lightness and good resistance to compression were also key selection criteria. ARPRO expanded polypropylene (EPP), an impact energy management material has a unique combination of properties that meet these material specifications and is also 100% recyclable.

The Space Brick uses a lightweight flame retardant ARPRO which provides flexibility in the moulded density range between 20g/l to 60 g/l. The lower densities provide maximum weight efficiency and increasing the density provides better stiffness and insert resistance. ARPRO’s structural strength means that 1m² of ARPRO 30g/l is able to sustain the pressure of 15t keeping 75% of its initial thickness and shape. Building is easy and solid joining is possible as a result of the flexibility and deformation of ARPRO.

The Space Brick functions as a thermal and acoustic isolator. ARPRO EPP brings temperature stability and helps to avoid temperature shock as a result of its low thermal conductivity. The acoustic properties of ARPRO act as an acoustic barrier by dampening or blocking sound.

The Space Brick was born out of a visit to show motorsport equipment to space engineers and illustrated the fact that many of the needs of space travel are similar to those of motorsport.

“This project is a perfect example of how our know-how in motor sport and dealing with their extreme conditions and needs can be transferred to the space sector and adapted accordingly”, said Diego Cagna, Special Application BU Manager presso Sabelt S.p.A.

Together with the expertise of The IES Group in Italy, a leading moulder with an innovative approach, the challenging Space Brick project became a reality. The collaboration between The IES Group and Sabelt shows how Made in Italy excellence can conquer space. The technology, from Formula 1 to space exploration represents a step toward new horizons, bringing with it the experience and innovation of two prestigious Italian companies.

Edoardo Clerici, Key Account Manager, The IES Group said, “Our experience has been applied in the innovative and highly technical field of aerospace, with excellent results. We are the bridge between the ARPRO material and the Space Brick solution.”

The Space Brick perfectly illustrates how a complex, lightweight three-dimensional object can be achieved using ARPRO as a mono-material.

If you have a project within the space field that could benefit from the Space Brick, visit Sabelt to learn more: www.Sabelt.com