News

JSP EMEA uses 100% electricy from renewable sources

JSP has renewed the green energy supplies in Estrées-Saint-Denis and Cheb for 2025.

JSP Uses Sustainable Permanent Net Solution for ARPRO Transportation

JSP, a global leader in engineered plastic foams, continues to enhance its innovative permanent net solution for transporting ARPRO to customers. Designed with both sustainability and efficiency in mind, this system also benefits from complying with the EU Packaging and Packaging Waste Regulation (PPWR) as reusable transport equipment and is exempt from disposable packaging requirements.

GID launches ARcycle, a premium quality rEPP

JSP is purchasing ARcycle from GID, a prime choice of rPP feedstock to enable the stable manufacturing of ARPRO with post-consumer recycled content (ARPRO RE).

Nuük, the smart cooler safely traces biological samples in real-time

Nuük is designed to transport products or samples that are part of a highly regulated sector with demanding requirements.

SALOMON launch the first fully recyclable ski and snowboard helmet

The Brigade INDEX ski and snowboard helmet can be fully recycled at the end of its life and represents a totally new approach to helmet construction, using 96% of materials from a single plastic family.

JSP supports leading international packaging provider’s commitment to circular economy with ARPRO RE 30%

Increasing the recycled content of automotive and HVAC components made from ARPRO is a significant step forward in sustainable manufacturing practices and aligns with the ambitious sustainability goals of automotive manufacturers.

JSP EMEA is the first EPP supplier to be certified by RecyClass

ARPRO Recycled grades produced at the manufacturing sites in France and Czech Republic are all RecyClass certified.

JSP and General-Industries Deutschland reinforce recycling partnership

JSP acquires a stake in the leading European EPP recycler General-Industries Deutschland GmbH.

BEWI select ARPRO 35 Ocean to showcase HVAC in the Plastic Pavilion at UIA 2023

The Plastic Pavilion is located in Gammel Strand, Copenhagen. As a result of the harbour-side location, BEWI selected ARPRO 35 Ocean EPP to showcase their HVAC products as it contains 15% recycled content from maritime industry waste, primarily used fishing nets and ropes.

LCA 2023

Significant carbon footprint savings in latest LCA results.

JSP EMEA is switching to bags made from 50% recycled PP content!

Grey is the new green! Based on our commitment to be as sustainable as possible, we have sourced a bag supplier within Europe that produces bags with 50% recycled PP bag content.

Why use ARPRO RE grades?

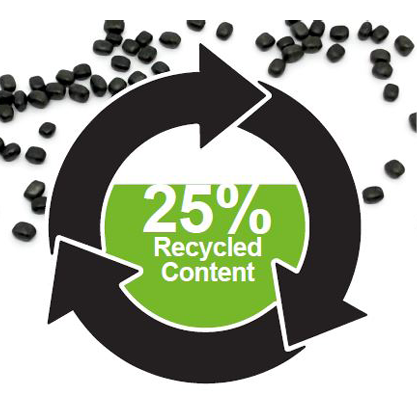

JSP has 14 years’ experience of manufacturing recycled grades. We offer grades with 25% recycled end-of-life EPP parts that have the same performance as ARPRO Black!

Stability test perfomed on ARPRO 5134 RE

Are you concerned about thermal degradation potentially reducing the mechanical properties of ARPRO RE grades? No need

JSP develops ARPRO REvolution with a recycled content of > 90%

ARPRO REvolution was born from a demand from EPP sectors to have more recycled material and at the highest rate possible.

Get the ARPRO CO2 Bonus at your factory gate

The world is changing and so are we. Our society and industry demand an increased awareness of the environmental impact on the way we live, act and on the products we consume.

ARPRO - not your conventional EPP

Today, ARPRO is the only Expanded Polypropylene with a certified environmental product declaration (EPD). This EPD helps select materials and optimise the CO2 footprint of your application in Life Cycle Assessment (LCA) modelling and reporting.

From Fishing Net to Particle Foam

A large part of the plastic waste in the sea comes from the maritime industry. The Danish company Plastix recycles such old fishing nets and ropes. The granulate produced is used by JSP International, among others, to manufacture expanded polypropylene (EPP).

ARPRO expanded polypropylene (EPP) is going full circle

We are applying a circular economy to provide continued use of resources. JSP uses newly produced material made from recycled EPP to produce its ARPRO 5134 RE with a recycled content of 25%. This not only saves resources but also reduces CO2 emissions by up to 12% compared with virgin material.

JSP is accelerating sustainability

JSP, the world’s largest supplier of expanded polypropylene is leading the way for a circular economy with recycled grades of ARPRO and assisting customers to create closed loop recycling system to help meet climate targets.

Circular Economy for Expanded Polypropylene (EPP)

Automotive Components Made of Packaging – Currently, recyclates are in high demand, including in the automotive industry. Materials producer JSP has developed an expanded polypropylene with 25% recycled content.

Polymer foam made from Maritime Industry Waste with 15% recycled content

Raw material manufacturer JSP is expanding its EPP (expanded polypropylene) particle foam range ARPRO, to include products made with recycled content.