Innovation

We continuously develop products and applications that provide customer and environmental benefit.

Design

Our engineers work with you in meeting your performance criteria as well as designing for manufacture.

We perform feasibility studies on initial part designs to evaluate molding feasibility and modification recommendations such as wall thickness, undercuts, mechanical core pulls, fill gun number/size/positions, number/positions of ejectors, shrinkage estimation, cavity orientation, micro venting management, passive steaming traps, insert position, installation and potential ARPRO grade nomination.

We can support your application development initiatives by using state-of-the-art design techniques in a confidential environment with the assistance of our experienced engineers.

FEA

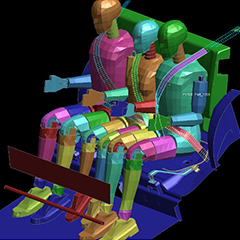

The ARPRO static and dynamic performance datasheets allow the construction of accurate material models for explicit Finite Element Analysis (FEA) codes, predicting performance under dynamic load such as crash or packaging drop tests.

Our proprietary ARPRO material models take the optimization of the ARPRO components a step further with our capability to evaluate the behavior of hybrid assemblies while predicting and countering the risk of undesired failure.

Our FEA methodology for designing production tools for complex applications like automotive seat cushions enables you to save cost and time and also helps to achieve dimensional tolerances, control warpage and eliminate costly secondary operations.

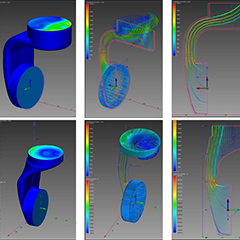

CFD

Using our ARPRO material models to perform CFD (Computational Fluid Dynamics) analysis brings tangible benefits through optimization of component geometry.

Prototyping

ARPRO prototypes are suitable for performance validation tests and cover the complete molded density range. Our years of experience have made us proficient in prototype design, complex assembly and sub-assembly with inserts.

Production

We perform process design optimization covering expansion, molding, secondary operations, quality inspection procedures and other operations.

Equipment configuration optimization covers expanders, molding presses, ovens, measurement equipment and much more.

A review of utility settings covers steam pressure, compressed air pressure, water temperature, water pressure and vacuum pump pressure.