Automotive

ARPRO manages impact energy by absorbing it, then returning to its original shape. ARPRO is ideal for multiple impact protection such as vehicle crash applications, and is widely used in automotive interiors to improve occupant safety.

ARPRO is "always on" keeping occupants safe even if the car is not running, or the electronics and associated sensors fail. ARPRO is a key component in pedestrian safety systems. ARPRO bumpers drastically reduce injury severity for pedestrians when compared to alternative materials or design approaches.

Metal wireframes can be incorporated into ARPRO allowing the removal of body-in-white elements leading to significant weight savings, improved fuel economy and reduced vehicle emissions.

Occupant safety

ARPRO is widely used in automotive interiors to improve occupant safety. Applications include; side impact protection, head impact protection, head rests, A B C pillar, knee protection and more.

An important safety benefit of ARPRO is its ability to withstand repeated impact and to return to its original shape, ready to deliver its safety performance time after time.

Pedestrian safety

ARPRO is a key component in meeting the requirements for pedestrian safety systems. ARPRO bumpers result in far lighter pedestrian compliant solutions, and need no additional space versus alternative materials or design approaches.

ARPRO bumper systems are up to 50% lighter and 20% faster in assembly, than alternatives, eliminating the need for secondary fasteners whilst bringing reduced tooling investments.

Expert design and unique material properties enable ARPRO bumper systems to deliver crash performance and pedestrian safety to Euro NCAP standards set against increasing space-restriction and styling demands, and are compatible with the latest generation of pedestrian safety sensors.

Stowage systems

ARPRO storage systems are space saving and efficient for the user. The ARPRO part is lightweight and contains shaped recesses for tools, jacks, wheels, inflation kit etc. This allows easy use and storage for all the car parts you hopefully never need.

If you want to see a stowage system in real life then…go to your car, open the boot and look for the tool box or spare wheel holders.

Weight reduction

We focus our optimisation efforts on achieving best performance at minimal system weight.

Metal wireframes or polymer elements can be incorporated into ARPRO resulting in hybrid material solutions which enables the reduction or elimination of structural components leading to significant weight savings, improved fuel economy and reduced vehicle emissions.

Different h-points for seats, corresponding to different body styles, can be engineered into the seat itself, reducing tooling costs and speeding up the development process.

Acoustical

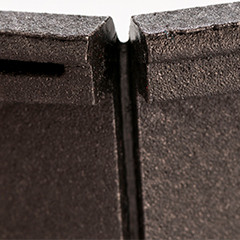

ARPRO complements its excellent energy absorption capability with impressive acoustic performance. The macroscopic tortuosity of ARPRO Porous absorbs incident sound waves resulting in an acoustic attenuation up to 3dBA vs. ARPRO Black for the main ARPRO Porous applications (tool boxes and seating).

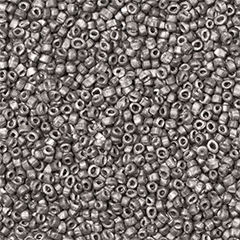

ARPRO is a unique, closed cell material that features air pockets (or voids) within the hollow cylinder-shaped particle structure; these enhance acoustic performance.

ARPRO Porous is used to reduce noise, vibration and harshness (NVH), with tests showing noise reduction levels of up to ten times that of alternative materials. ARPRO Porous is used extensively in car interiors to reduce noise levels without increasing weight.

Surfaces

The aesthetics of ARPRO are incredibly versatile, with options ranging from colours, surface textures, and fabric coverings.

Tool surface treatment and finishing techniques make it possible to generate a wide variety of patterns in various sizes and depths. The excellent post expansion ability of ARPRO enables superb quality surfaces that can be used in visible aesthetic applications.

In addition, snap fit, tight tolerances enabling precision parts, living hinges and the ability for complex shapes make ARPRO a unique material.