Packaging

ARPRO outperforms other materials in returnable packaging by being extremely lightweight and exceptional in impact and damage protection.

We can help you design custom in-molded packaging to cradle and protect your product. Or you can choose high performance returnable packaging available in a wide range of standard sizes.

Environment

In an industry with increasing concerns for environmental performance, reducing environmental impact through re-usable packaging is important. Use of re-usable packaging is extending beyond the automotive industry (where it is called dunnage) to traditional ‘delicate’ components such as glass, electronic or painted parts, as the next phase of minimizing costs are found in process efficiencies.

Re-usable packaging containers not only protect parts in transit, but they make packaging and shipping easier (by reducing materials needed and time taken) and help to make unpacking and assembly more efficient.

Dunnage

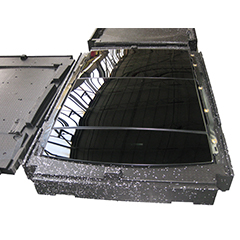

The durability of ARPRO allows for multi-use, transport ready packaging for many different types of components and sensitive products. Dunnage can be custom-designed or standard size industrial totes with varying heights are available.

Food packaging

The lightweight, durable and thermal insulation properties of ARPRO make it a widely used and ideal material for food packaging and catering boxes. ARPRO is easy to clean, reusable and designed for use in both hot and cold conditions.

ESD

Electrostatic Discharge (ESD) grades of ARPRO are available for molding and fabricating packaging materials used for sensitive electronic equipment and other products where static discharge is undesirable.